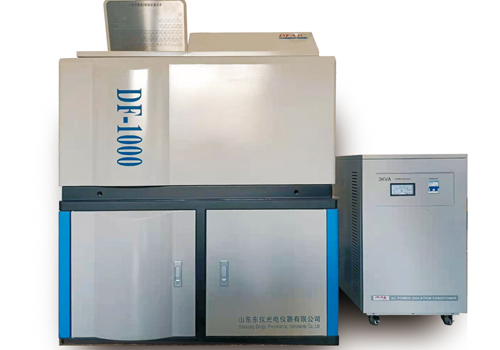

Fluorescence spectrometer

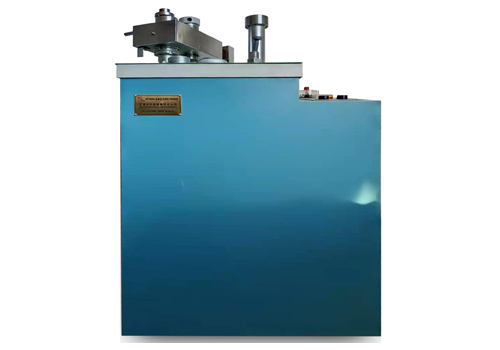

Pressure prototype

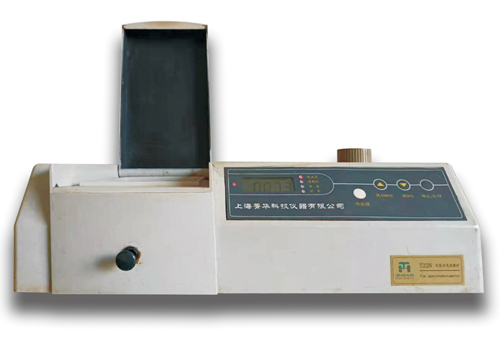

Spectrophotometer

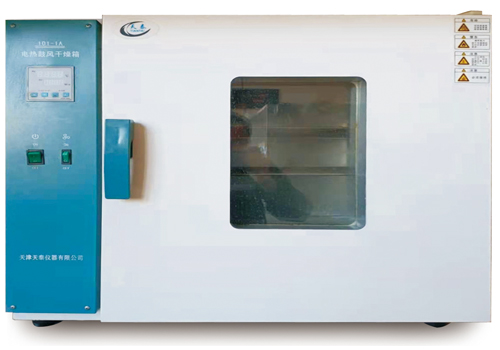

Drying oven

Infrared carbon and sulfur analyzer

Grinding prototype

The quality control of high carbon ferrochromium production is a very important part of our factory's production process. We have taken a series of measures to ensure stable product quality and meet customer requirements.

Firstly, we attach great importance to quality control in the raw material procurement process. We are committed to establishing long-term partnerships with reliable and qualified suppliers to ensure that the source of raw materials is reliable and meets standards. When the raw materials enter the factory, we will conduct strict inspections and sampling tests to ensure that the composition and quality of the raw materials meet the requirements.

During the production process, we strictly follow the process flow and operating specifications. We have a professional production team who have undergone professional training and are familiar with production processes and operational points. We use advanced production equipment and monitoring instruments to monitor the production process in real-time and record data to ensure that each step of the operation meets standards.

At the same time, we conducted strict quality inspection and sampling testing. We have established a dedicated quality inspection department responsible for sampling and comprehensive inspection of key links in the production process. We use advanced testing equipment and methods to test key indicators such as composition, hardness, density, etc. of the product to ensure stable quality.

In addition, we also focus on product traceability and recording. We identify and record each batch of high carbon ferrochromium produced, including information on the source of raw materials, production time, production process, etc. This can ensure the traceability and traceability of the product. Once quality problems occur, we can promptly track specific batches and processes and take corresponding corrective measures.

Finally, we also conducted a customer satisfaction survey and collected feedback. We regularly communicate and communicate with customers to understand their needs and feedback. We use customer feedback and suggestions as an important basis for improvement, continuously optimizing our quality control system and production processes.

In summary, we ensure the stable quality of high carbon ferrochromium products and meet customer requirements through strict raw material control, production process control, quality inspection, and customer feedback measures. We will continuously improve and optimize our quality control system to provide customers with higher quality products and services.